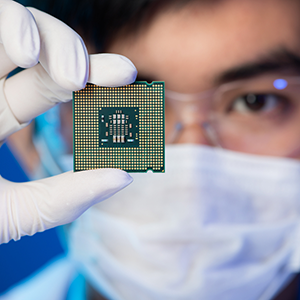

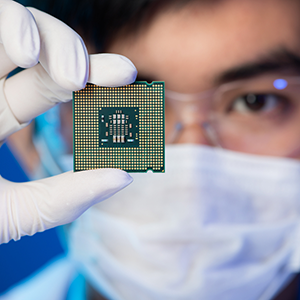

System LSI testing service

In recent years, a number of high-performance, multifunctional system LSIs have been developed by miniaturization of processes and development and automation of design tools. At the same time, a wide range of knowledge and high technical skill is required for test development and evaluation work of system LSI. In addition, higher cost of corresponding test systems, related equipment, jigs etc., and increase in test cost due to prolonged test development etc. have become conspicuous. In this situation, our company has comprehensive services related to the testing of system LSI.

In recent years, a number of high-performance, multifunctional system LSIs have been developed by miniaturization of processes and development and automation of design tools. At the same time, a wide range of knowledge and high technical skill is required for test development and evaluation work of system LSI. In addition, higher cost of corresponding test systems, related equipment, jigs etc., and increase in test cost due to prolonged test development etc. have become conspicuous. We believe that we can propose and provide timely and reasonable test environments and solutions through comprehensive services related to system LSI testing under these circumstances.

What is required for failure analysis is that the analysis TAT is short and the cause can be clarified. Analysis preparation point Analysis is possible by directly connecting the tester and analysis device so that device failure can be reproduced and observed at the time of analysis. In order to prepare CAD data for shortening time, we can utilize powerful navigation function and analyze efficiently. Analysis by service item purpose (prototype analysis / reentrant analysis / yield analysis) Analysis of phenomena of DC failure and function failure Analysis possible with both wafer and package Preparatory work such as package opening, opening of socket etc.